Dongguan Changfeng Environmental Technology Co., Ltd.

Dongguan Changfeng Environmental Technology Co., Ltd.

Contact: Mr. Jiang

Contact: Mr. Jiang

Tel:13528666492

Tel:13528666492

Landline:0769-82726001

Landline:0769-82726001

Address: Busheng Building, Environmental Protection Industrial City, Shatian Town, Dongguan City, Guangdong Province

Address: Busheng Building, Environmental Protection Industrial City, Shatian Town, Dongguan City, Guangdong Province

Operational Problems of Sludge Dewatering in Sewage Plants at Low Temperatures

Since 2021, the violent cold wave has continuously invaded various places. The sewage treatment plant has entered the stage of low temperature operation, especially in areas where the temperature changes greatly in the four seasons. The impact of this low temperature is even more serious. The sewage treatment plant has begun to operate in the middle of the year. In the most stressful season, various operating indicators will appear to be operating in a completely different state from summer as the temperature drops. In the previous official account, many aspects of winter operation have been discussed. In this issue, I will discuss the pollution Mud dewatered in winter running.

As the operators of sewage plants, most of them feel this way. After winter, the sludge dewatering capacity and efficiency of the sewage plant will decrease to varying degrees. The same agent and the same equipment operate in the summer to desludge. The effect is good, the water content of the sludge cake is low, the processing capacity is large, and the working time is correspondingly short. However, during the winter, the desludge effect decreases, the moisture content of the sludge cake increases, and the treatment volume becomes smaller. In order to ensure that sufficient sludge is transported out of the system, a longer operation is required to ensure the remaining sludge in winter. Stable emissions.

The decrease in the ability of sludge dewatering in winter will cause the sludge concentration to rise, while the water temperature in winter decreases, and the microorganisms that produce foam and filamentous bacteria in the composition of activated sludge enter the suitable growth period, and the sedimentation performance of the sludge becomes worse. The dewatering of sludge with reduced settling performance and capacity will form a vicious cycle of poor dewatering of excess sludge, which will greatly reduce the ability of dewatering and removing excess sludge from the system during winter. The rich surplus sludge will cause sludge aging and sludge foam to occur frequently in winter. Therefore, sludge dewatering during winter becomes an important control link for the stable operation of wastewater treatment plants.

The change of microorganisms in winter is caused by the drop in water temperature, but the efficiency of sludge dewatering has decreased. Apart from the factors that affect the adaptability of microorganisms to temperature changes, are there any influencing factors of its own? Can these factors be adjusted in daily management to avoid or eliminate the impact?

In the sewage treatment plant, the sludge needs to be dewatered by adding flocculants, mixing and stirring, and then entering the dewatering machinery for dewatering. Dewatering machinery is mechanical equipment, and will not produce corresponding changes to temperature changes, so it is necessary to analyze the winter and summer reactions of the flocculant.

Flocculant is a long-chain polymer of high molecular weight. It is an organic compound such as polyacrylamide. Polyacrylamide has a large molecular weight and long molecular chain. During the dissolution process, it is through the Brownian motion between water molecules and organic molecules. A solution is formed, and the Brownian motion between molecules is greatly affected by temperature. Generally speaking, as the water temperature decreases, the Brownian motion intensity of the particles also weakens, the hydrolysis rate of the flocculant is slow, and it takes time to form a mature flocculant solution. Growth; In addition, the flocs formed by the flocculant and sludge are fine and loose at low temperatures, and the clarification effect becomes poor. There are data records: when the temperature is 4-20 ℃, the flocs form faster. When the water temperature is above 20°C, it has no great influence on the coagulation effect.

Under normal circumstances, the flocculation effect will be improved when the water temperature rises, but under low temperature conditions in winter, you can improve the flocculation effect by increasing the amount of flocculant. At the same time, you can consider placing a heating device on the flocculant dissolving tank to improve the dissolving tank The temperature of the inner liquid can improve the dissolution rate of the flocculant and the temperature of the solution, so as to better play the role of the flocculant.

Therefore, from the perspective of the dissolution and maturation of flocculants, sludge dewatering in winter will also be affected to a certain extent. In addition to the problem of flocculants, the extracellular substance EPS of activated sludge in winter also has an impact on sludge dewatering. The corresponding impact. Some studies have shown that the low temperature in winter will make the activated sludge produce more EPS to maintain its activity. The increased EPS will increase the viscosity of the activated sludge, and the increased viscosity of the sludge will cause corresponding dehydration problems. The increased viscosity of the sludge will increase the difficulty of washing the filter belt of the belt filter, causing the filter belt to run off. And other phenomena appear; the adhesion of the sludge of the plate and frame filter press to the filter cloth increases, and the initial mucosal layer is formed quickly, preventing more water from filtering out of the filter cloth; the screw press is in the thickening section after the viscosity of the sludge increases. The gap between the dynamic and static rings of the sludge sticks together, resulting in poor drainage of the water in the sludge and an increase in the moisture content of the mud cake; the centrifugal effect of the centrifuge will also be affected by the increase in viscosity and become worse, and the liquid ring will become thinner, resulting in mud Cake moisture content increases. Academics have shown that the dewatering performance of sludge and the moisture content of sludge are closely related to the increase in sludge viscosity. Therefore, the EPS changes from the seasonal temperature protection of activated sludge itself in winter will also dehydrate the sludge. Have a big impact.

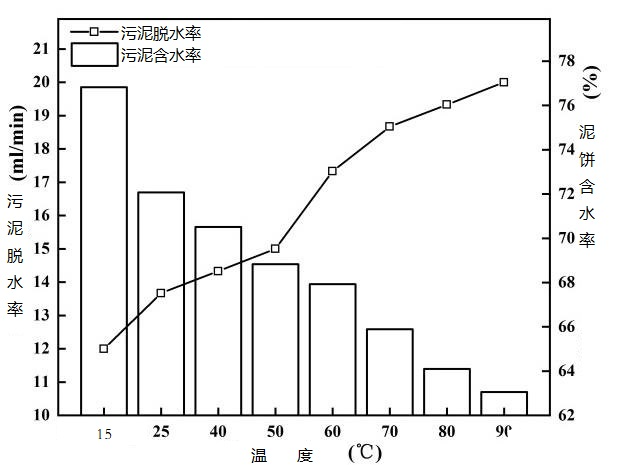

Also in some studies, it has been shown that temperature has a relatively large effect on the sludge dewatering rate and the moisture content of the sludge cake after dewatering. From the temperature change and the change curve of the sludge dewatering rate and the moisture content of the mud cake, it can be seen that the sludge The dehydration rate will increase as the temperature rises, and the moisture content of the mud cake will decrease as the temperature rises. This also shows that under the same production conditions, temperature will also have a great impact on sludge dewatering.

The analysis of the above data shows that the sludge dewatering of the sewage treatment plant is affected by the low temperature during the winter operation. The microbial population of the activated sludge itself changes, the EPS changes outside the microorganisms, the solubility of the flocculant, and the sludge dewatering rate. And changes in the moisture content of the sludge cake will have a great impact, and almost all move in the direction that is not conducive to the production of sludge. In sewage plants, maintaining stable production of sludge in winter is a prerequisite to ensure good activity of activated sludge in the biochemical system. During operation, the impact of low temperature on all aspects of sludge dewatering should be fully considered, and corresponding heating measures should be taken. , And the insulation of the workshop, to improve the low temperature environment of sludge dewatering, so as to ensure the stable and orderly development of production.