Dongguan Changfeng Environmental Technology Co., Ltd.

Dongguan Changfeng Environmental Technology Co., Ltd.

Contact: Mr. Jiang

Contact: Mr. Jiang

Tel:13528666492

Tel:13528666492

Landline:0769-82726001

Landline:0769-82726001

Address: Busheng Building, Environmental Protection Industrial City, Shatian Town, Dongguan City, Guangdong Province

Address: Busheng Building, Environmental Protection Industrial City, Shatian Town, Dongguan City, Guangdong Province

Discussion on On-line Monitoring of Biochemical Pool in Wastewater Treatment Plant

As a sewage treatment plant, the core treatment structure is the biological reaction tank, which carries most of the removal of organic pollutants and nutrients. Whether the water quality reaches the standard is directly related to the management of the biological reaction tank. Operation People’s understanding and management of biological ponds are also constantly strengthened, and they hope to manage biological ponds through more refined data. However, at this stage, traditional sewage plants rely on less data on biological ponds, and they cannot form effective refinements. As the production technology and measurement level of online equipment is getting higher and higher, how to use the online monitoring instrument to realize the precise management of the biological pool by the process personnel of the sewage plant?

Before understanding the application of online meters, let's take a look at the biological pool data that the wastewater treatment plant can master without online. A laboratory is built in the sewage plant, and the laboratory will test the daily incoming and outgoing water quality, the activated sludge parameters in the biological tank, etc., and obtain the operating data for the process personnel to adjust and use. It is subject to the limitations of the test method and the laboratory personnel’s Working hours, etc., these data are generally tested once a day.

The sewage treatment plant laboratory controls the test parameters for activated sludge in the key biological pools. The more commonly used are sludge concentration, volatile sludge concentration MLVSS, sedimentation ratio SV, dissolved oxygen, microbiological microscopic inspection, etc., and the time for manual sampling , Cycle and the restriction of the flow direction of the water flow in the biological pool, the end of the biological pool is generally selected for sampling. The laboratory data at this point mainly monitors the result of the final reaction of the activated sludge in the biological pool to various pollutants in the sewage. General traditional professional books are also using the data at this point to determine the routine detection parameters of the biological pool. For example, the conventional term for dissolved oxygen is 2mg/L, but in the entire aerobic pool, the dissolved oxygen in the front stage is due to more organic matter in the water, and a large number of microorganisms adsorb and degrade the organic matter, which consumes a lot of oxygen. Dissolved oxygen is far below 2mg/L, but with the extension of the aeration area, the organic pollutants in the sewage are gradually degraded by microorganisms. The microorganisms no longer need oxygen, and the remaining dissolved oxygen in the water will gradually increase. Waste, generally control the dissolved oxygen at 2mg/L at the end of the aeration zone of the biological tank, which can reduce unnecessary energy consumption and also has a good control on the aging of activated sludge.

Therefore, in the monitoring at the end of the biological pond, traditional data can be used to judge the degree of sewage treatment by the activated sludge in the biological pond, and the craftsmen use these data for daily process adjustment and management. However, at the end of the test and the frequency per day, there is also a large lag in the overall process control of the effluent water quality results. The manual test in the laboratory is actually a result test, but it advances the results of the effluent water quality test to the biological At the end of the pool, there is no process detection of biological reactions, and it is even more powerless to predict in advance. Under the strict control of the effluent quality at this stage, there are higher levels of requirements for process operation. The original result detection needs to Before entering the process for detection, it is even necessary to have the ability to predict. It is difficult to achieve this goal in the existing manual detection mode.

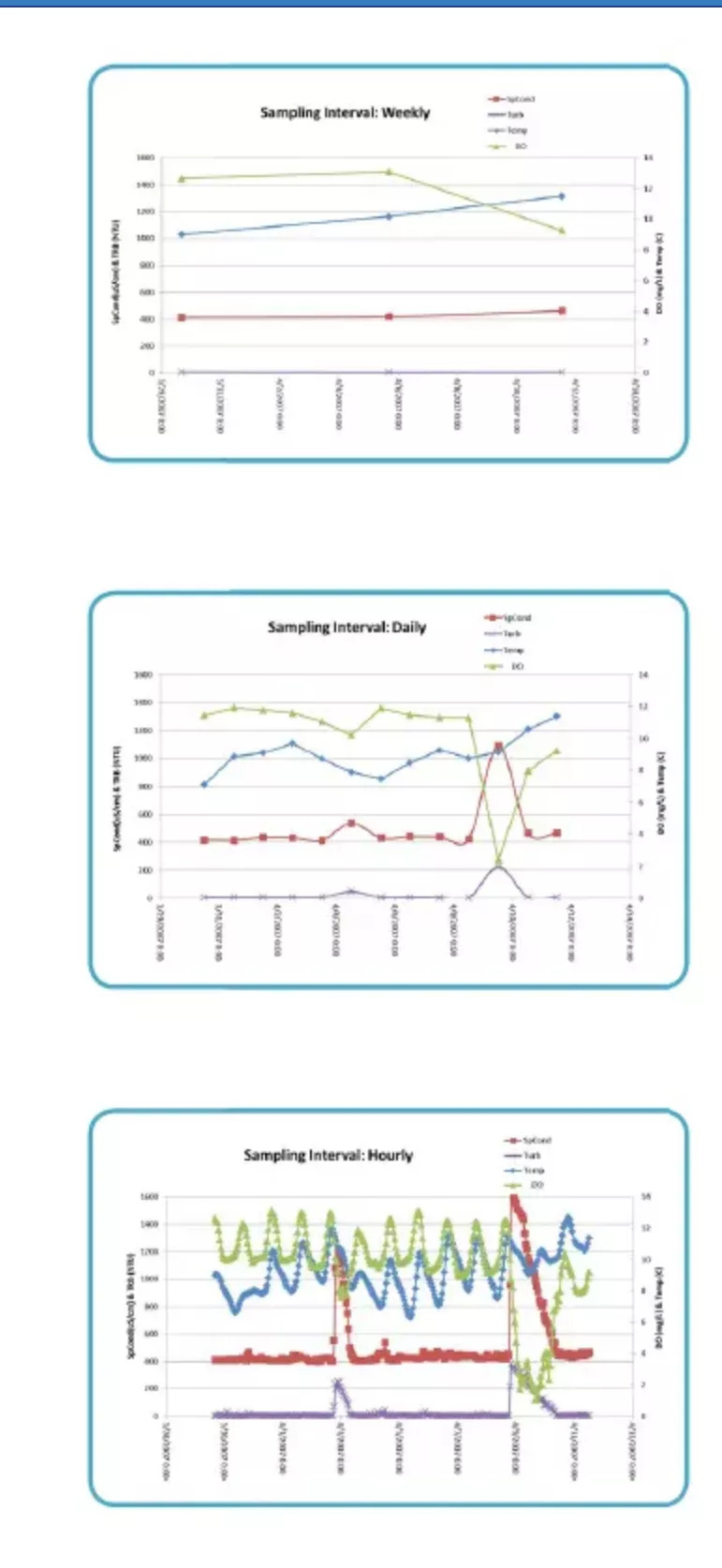

At the same time, the detection density of the data also brings the inaccuracy of the process control. The biological treatment process of the sewage treatment plant is a fluid process, the flow treatment process, the water quality data, and the process data change in real time with time and space location. When sampling, only instantaneous water samples at a fixed location can be taken. It is impossible for instantaneous water samples to represent all changes in the entire biological pool. Only when the density or number of sampling points is large enough, will there be more suitable data, so this requires a long-term stable test, and ensure that the process, water intake, environment, etc. are in a relatively stable state. There will be, but it is actually impossible at this time. Therefore, the manual sampling of laboratory results must accumulate as much data as possible, and eliminate the accidental sampling in the large amount of data, so as to have the basis for judgment. The following are a few For the data curve graphs of different detection frequencies, we can compare the difference of the data monitoring frequency:

It can be seen from the figure that the monitoring frequency (week, day, hour) is different, and the degree of response to process changes is also very different. The more intensive the monitoring data, the more timely the monitoring of changes that occur in the process, the more effective the process The more effective the control measures are taken, the better the management of the biological treatment process. However, this kind of high-density monitoring cannot be accomplished by only relying on manual means. It can only rely on online instruments. Therefore, online instruments play a very important alternative to manual testing.

In terms of data intensiveness, online instruments can completely replace manual labor. In addition to having more intensive data, is it possible for process managers to move control forward through the use of online instruments? The control of the previous movement needs to monitor the various stages of the process operation. The biological pool is moved from the original terminal effluent monitoring to the in-process monitoring. The biological pool has more spatial push-flow processes (SBR and its variants change in time Mainly), the point monitoring values in different processes are different, and the monitored data in different periods will also change. Under real-time changing working conditions, the frequency of manual detection is low and the cycle is long. The shortcomings are obvious, and the advantages of real-time monitoring of online instruments are obvious. Therefore, it is hoped to adopt the process control of the sewage treatment plant in the previous process, and there is an increasing need for the real-time monitoring of online instruments in the process operation. The following uses the control points of the biological pond to illustrate the application of the offline instrument in the process control of the biological pond.

There are various types of biological ponds for sewage treatment, and different processes require different process tank bodies. The following is the A2O process control point to discuss the application of on-line instruments. In the existing dephosphorization and denitrification process, A2O and its improved processes are more and more used in practice. The more important features of the A2O process are the anaerobic stage (A) that adsorbs excessive phosphorus and the anoxic stage of denitrification. Section (A) separates a separate control area for control, and has clear management parameters in process management, which is convenient for actual operation management. For process managers, only the online meter of dissolved oxygen and sludge concentration installed at the water outlet can no longer detect the effect of phosphorus and nitrogen removal. This requires more updated equipment or some commonly used characterizations. Parameter such as dissolved oxygen, ORP, nitrate nitrogen meter, etc. to evaluate the effect of dephosphorization and denitrification, so as to adjust and control in the later management.

Before realizing the improvement of management and control capabilities of online instruments, it is necessary to clarify the content of process control and the detection instruments that can be used at this stage. Only on the basis of a full understanding of the process and monitoring equipment, can it be possible to choose a reasonable monitoring method for process control. For dephosphorization and denitrification, biological dephosphorization and biological denitrification are the most economical and natural removal processes. The conventional A2O process for dephosphorization and denitrification in sewage plants at this stage uses functional areas to remove different nutrients. The mechanism of biological phosphorus removal and biological nitrogen removal has been discussed in the previous articles, so I won't expand it here. What you need to know can be read through the official account of the album "Phosphorus Gate One Foot" and "Is Nitrogen Removal Hard".

After understanding the sewage treatment process in the biological section, it is necessary to understand the instruments that can be used at this stage. The instruments that can be used in the biological pond of the sewage plant mainly include the dissolved oxygen meter DO, the sludge concentration meter MLSS, the oxidation reduction potential ORP, and the nitrate state. Nitrogen meter NO3-N, level gauge, etc. Different manufacturers have different monitoring methods for these meters, such as ultraviolet, fluorescence, electrolyte, etc. For users, they don’t need to understand these monitoring methods, but only need to understand what kind of data it can provide. Now, let’s discuss the application of these types of instruments in the biological pool.

The general content of the instruments and meters in the biological tank is that the installation conditions are met. The A2O biological tank is a push-flow reaction vessel, and the activated sludge inside is in a suspended mixed liquid state, which requires different equipment to provide sufficient stirring power To meet the suspended state of the biological pool. The water quality monitoring data of the meter requires a relatively stable environment to obtain more accurate data. Therefore, the meter should be installed in an area where the water flow is stable. Do not install it in the mixing equipment. The data fluctuations caused by the fast water flow produce data with weak regularity, which lacks guiding significance. However, it should be noted that stable water flow is not equal to a hydraulic dead angle. In some biological ponds, there are hydraulic dead angles in some local areas. At the hydraulic dead angle, a muddy water layer often appears, and the activated sludge cannot fully contact with the sewage to react. Various environmental parameters are also misleading, and the installation location should avoid possible hydraulic dead ends. The installation depth is generally 1 to 1.5 meters below the liquid surface. This can avoid the deviation of the measured value caused by the layered precipitation of activated sludge on the surface, and the data deviation caused by the disturbance of the surface airflow can also be better. Avoidance, during operation, there may be some cases where the liquid level drops after the biological pool is out of service, and excessive installation will cause the probe to be exposed to the air; there are usually more suspended impurities and sludge foam accumulation on the surface of the biological pool When working conditions occur during operation, avoiding these impurities on the surface can play a good role in protecting the probe.

DO (Dissolved Oxygen Detector), A2O process divides different functional areas through the difference of dissolved oxygen to meet the process requirements of phosphorus and nitrogen removal. Therefore, monitoring the dissolved oxygen in each functional area is the most basic for biological phosphorus and nitrogen removal. One of the control parameters, the conventional parameter requirements: the anaerobic zone is about 0.1mg/L, the hypoxic zone is ≤0.5mg/L, and the end of the aerobic zone is about 2mg/L. Of course, in actual operation, the range of dissolved oxygen can be adjusted according to the actual good effluent water quality of each plant. For example, more and more sewage plants have adjusted the internal reflux ratio to dissolve the position of the outlet of the aerobic zone. The oxygen control requirement is lower, even below 1mg/L, to meet the requirement of low enough dissolved oxygen content brought back by the internal reflux to meet the anoxic environment of denitrification. Dissolved oxygen is the basic control parameter for the division of A2O process functional areas. The installation of sufficient and accurate DO instrument is the requirement for A2O process control. In actual use, it is necessary to install a dissolved oxygen instrument in the stable area of each functional area. In order to detect the dissolved oxygen status of the functional area.

MLSS (Sludge Concentration Meter), the sludge concentration meter can detect the amount of activated sludge in the biological pond, and the amount of activated sludge is a basic calculation parameter for the various operating indicators of the biological pond, including the sludge load F /M, sludge index SVI, organic content MLVSS/MLSS and other calculations require MLSS data, advanced detection technology can directly detect the MLSS value through the probe, no longer need to pass more than two hours of drying in the laboratory, constant Weighing, weighing, and calculating the value. The directly detected MLSS value can quickly reflect the change in the amount of activated sludge in the biological tank. For the control of the concentration of activated sludge through the discharge of residual sludge, as well as for the operation Some failures, such as the reduction of the return flow caused by the failure of the external return pump, the stratification of activated sludge caused by the failure of the agitator and the fan, etc., have rapid data response. The operator can quickly perform the activated fouling in the biological pool according to the online MLSS. The judgment of the amount of mud is used to make corresponding process adjustments. Theoretically, the sludge concentration in the biological pond is evenly distributed. However, since the biological pond is a process of mixing the front-end water inlet and the backflow, and the whole process of completely mixing and pushing the flow, in practice, there is a low front end and a high back end. A complicated change situation affected by the setting position of the backflow and push-flow agitators. In order to reduce the data offset caused by these uncertain change factors, the sludge concentration detection is generally selected at the outlet position.

ORP (oxidation-reduction potentiometer), for phosphorus and nitrogen removal, the conditions can be judged by the chemical method of electron transfer and oxidation-reduction. By detecting the oxidation-reduction potential, the reaction conditions for phosphorus and nitrogen removal can be indirectly judged. Therefore, the use of ORP can improve the process management personnel's judgment on the process of the dephosphorization and denitrification reaction. Detect the reaction by empirical ORP range value of each reaction

Since ORP mainly detects the biological reaction of dephosphorization and denitrification, the ORP instrument is mainly set in the anaerobic zone and the hypoxic zone to detect the progress of the biological reaction.

NO3-N (nitrate nitrogen detector), with the in-depth development of the denitrification process, the presence of nitrate nitrogen in the biological pool that changes during the denitrification process can be detected, and the progress of nitrification and denitrification reactions can be judged (the difference lies in the installation Location), the conversion of ammonia nitrogen into nitrate nitrogen is a nitrification reaction. The nitrate nitrogen at the aerobic end can be detected to determine the progress of the nitrification reaction; the nitrate nitrogen detection in the anoxic zone can determine the nitrate nitrogen in the anoxic zone To determine the removal effect of total nitrogen, in some A2O improvement processes, it is divided into one-stage and two-stage hypoxia, and the content of nitrate nitrogen is detected separately, which can judge the removal effect of nitrate nitrogen and better determine the system The change of total nitrogen has a positive effect on the addition of carbon source, the control of internal reflux ratio, and the control of dissolved oxygen.

The level gauge, as a level meter, can detect the liquid level of the biological pool, especially in multiple parallel processing lines, use the same set of gas supply pipelines, and can adjust the height of the outlet weir to adjust the level of the biological pool. It is necessary to check the liquid level of the biological pool to maintain the balance of multiple parallel processing lines, so as to ensure the balance of the air outlet pressure of the air supply pipeline, so that the air supply is also balanced, and it is convenient to control the process. Generally need to be installed on each process line.

In addition to these commonly used meters, there are also some meters that have some applications in biological tanks, such as a pH meter, which can indirectly detect the consumption of alkalinity after nitrification. It is more suitable for some sewage with high ammonia nitrogen; SOUR meter, through Respiration rate can be used to judge the changes of biological reactions. It can detect the biological activity of activated sludge and estimate the reaction effect of the biological pond. Now there are ammonia nitrogen probes and total phosphorus detection probes that use the latest detection technologies to more directly detect biological removal. The reaction effect of phosphorus denitrification.

After knowing so many parameter probes that can be used in practice, how can the sewage treatment plant really play the role of its probes to improve production in actual use? In this issue, I will discuss the online monitoring of the sewage plant biochemical tank. Applications.

When the sewage plant collects a large amount of data through the probe set in the biochemical tank and enters the central control computer of the sewage plant, the collected implementation parameter data will eventually become the historical data of the operation of the sewage plant. These historical data are in most sewage plants. Without sufficient attention, the process management personnel in the wastewater treatment plant do not believe that these data can play a supporting role in the management process, resulting in a large amount of data being stored in the computer hard disk and eventually lost.

There are many reasons for this situation, and a considerable part of the reason is that the process management personnel lack sufficient data analysis capabilities, and are unable to conduct correlation analysis on these large amounts of operating data, and seek from these large amounts of data. Relevance. At the same time, the larger the amount of data, the more difficult it is to analyze and sort, and the less likely it is to find the fit and correlation between the curves. In the sewage plant, the process personnel still maintain the traditional way of operating experience to guide the daily management. They believe that their feelings are far more reliable and more operational than these instrument data.

I don’t deny that in many cases, the experience of the operators has brought some improvements and improvements in the process operation, but in some cases, the experience of the process personnel cannot be combined with the real operating data, which will make many experience values erratic. Obviously took the same operation as last time, but it has not been improved very well. This actually reflects that pure accumulation of experience is often not enough to deal with complex changes, and these changes can be derived from more comprehensive and detailed data. This is the difference between data and experience.

Operators who rely on long-term experience are not accustomed to analyzing data changes. When ignoring the data generated by these meters, the operators will forget the existence of these meters in the management, and they will not pay enough attention to them. No longer pay attention to the basic maintenance requirements of the instrument in the middle. After the instrument is damaged, the inquiry found that the cost of replacing the instrument is very high. Combined with the daily neglect of these data, it is natural to calculate through simple input and output. These instruments will no longer be expensive to maintain.

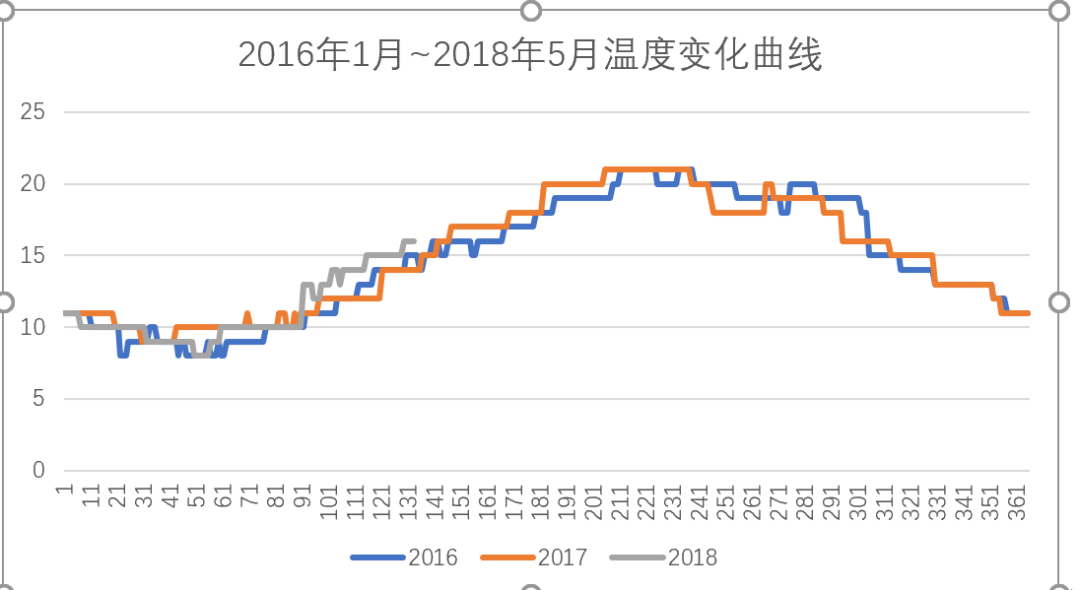

However, after operation managers can analyze the laws reflected by the data generated by these instruments, they will be better managed and controlled. In the actual operation of the sewage plant, the domestic water consumption habits of the residents in the same area show a certain regular change within a certain time frame. This regular change and seasonal changes, living habits, work and rest habits, etc. have great changes. The relevance of this kind of regularity can be superimposed and overlapped very well through the data curve. This regularity reflected by the data is more accurate and forward-looking. Process operators can make corresponding management and control measures through this data change, so that the operation and management of the wastewater treatment plant will become pre-management, and adjustments can be made before regular seasonal changes, so as to obtain better management.

Through regular analysis, the formulated pre-management measures have reduced the loss of manpower and material resources caused by a large number of passive process control. This cost often exceeds the replacement cost of field instrument probes, so that the input and output can be balanced. Even profit. This is the cost savings brought about by the improvement of the soft power of the sewage plant. This saving is more technical and less easy to be discovered by the management personnel. The automatic control probe and the automatic control data in the undiscovered soft power improvement chain are also discarded. On the one hand, it becomes a kind of furnishings in the sewage treatment plant.

However, with the update of big data computing technology and the continuous expansion of AI technology for analyzing and learning massive data, it is possible to search for the regularity and relevance of the massive data generated by sewage plants every day. AI technology with learning ability can continuously learn a large amount of data generated in process changes, and obtain guiding opinions that are more in line with the actual operation of a sewage plant.

In addition to the collection and AI learning, the operable guidance is also extremely important. It is also a reasonable algorithm, which is based on the principle of biochemical treatment, or the control points of some sewage treatment processes, or it can be in the sewage plant. Some unique process settings, etc., have become the basis of important algorithms for data analysis. This is also lacking in the control room monitoring software of many sewage plants in the design, that is, the lack of automatic control technicians and a deepening of senior process management personnel. The two parties should combine the process water quality probe with the process requirements of the wastewater treatment plant management and control, and introduce new calculation techniques to truly bring out the control function of the wastewater treatment plant’s central control system, and make the wastewater treatment plant control from human experience. Break away, use data to guide production, use computing technology to change the extensive management, and achieve management optimization and improvement.

Good and effective process control requires more accurate data to achieve. The improvement and promotion of each link in the data chain is very challenging for the sewage treatment plant and requires more professional technology. With local investment and research and development, the bright prospects of process control in wastewater treatment plants can only be achieved through long-term efforts and persistence. I hope that more professionals will pay attention to the development and application of computing technology for process control in wastewater treatment, and contribute to the common cause of water environment. Hard work.